- Home

- /

- Telescopic slides up to...

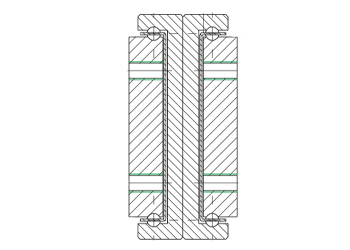

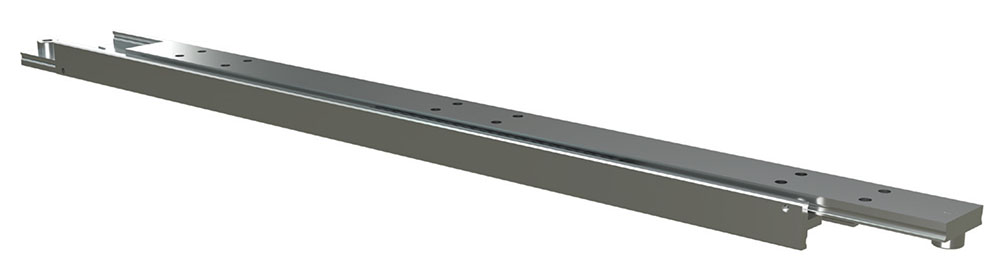

Telescopic slides up to 2,500 kg/Pair.

Milled SCHOCK® telescopic slides for very high load capacities.

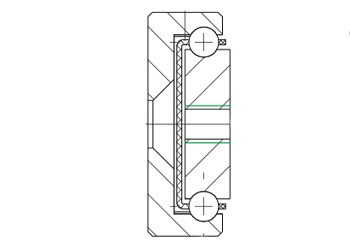

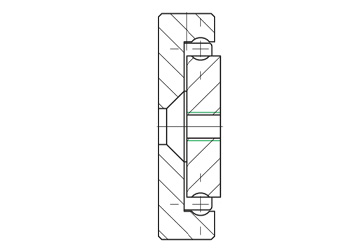

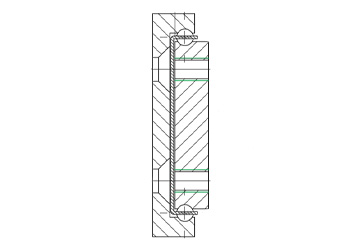

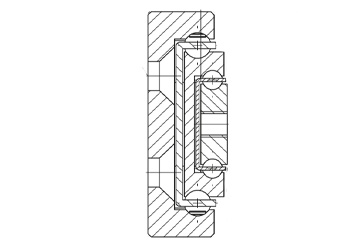

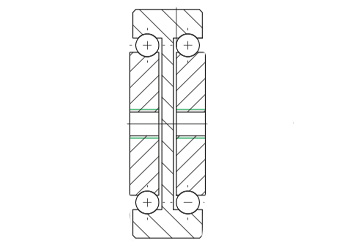

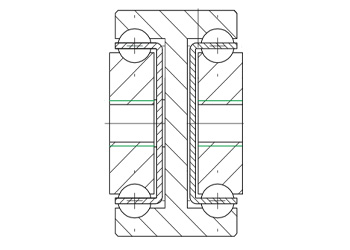

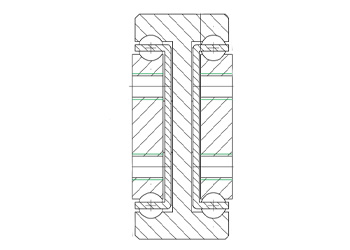

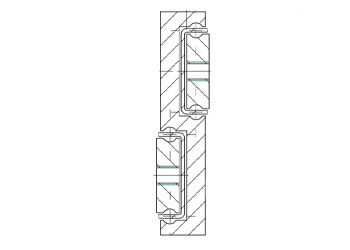

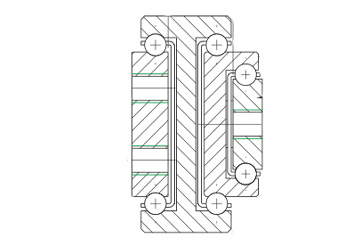

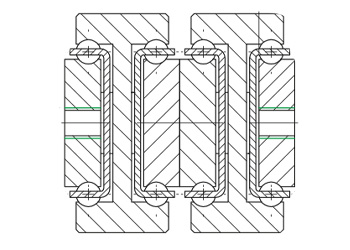

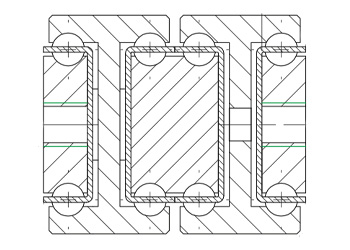

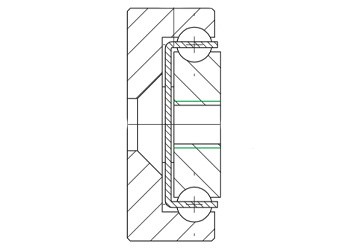

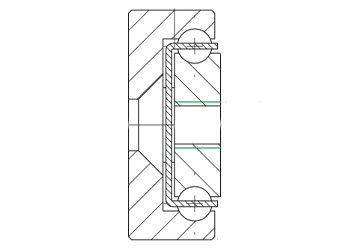

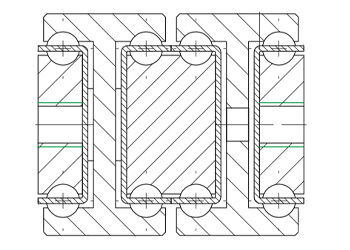

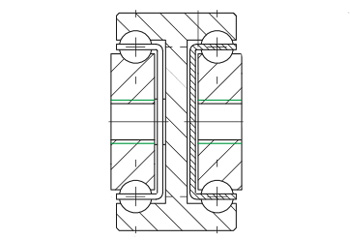

Telescopic slides partial extensions 50%

Steel (C45E+C) galvanized, milled and hardened raceways, extendable on one or both sides.

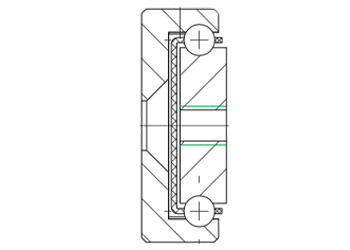

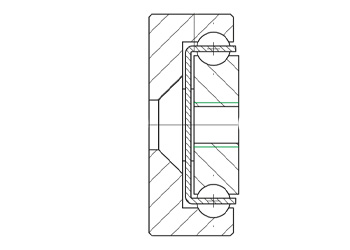

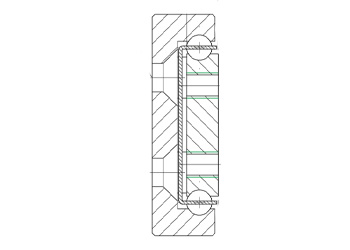

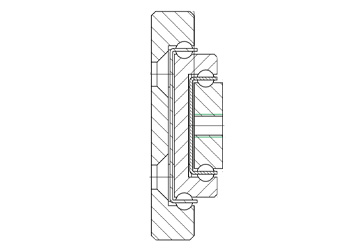

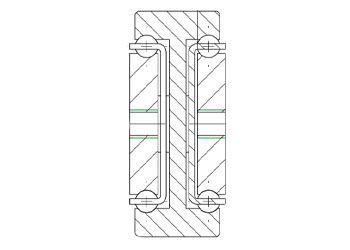

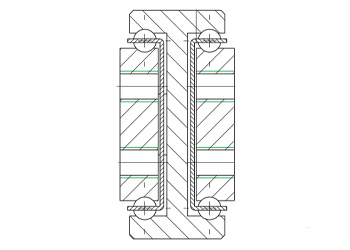

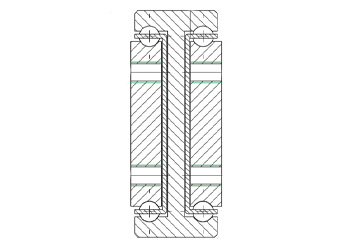

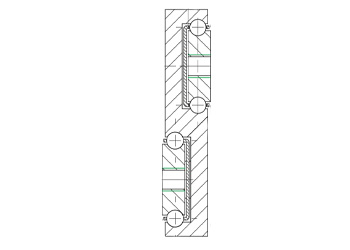

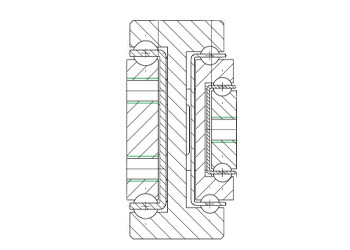

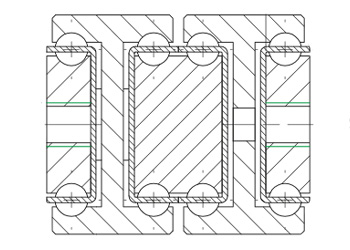

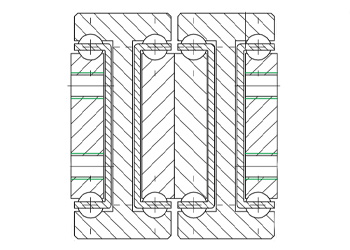

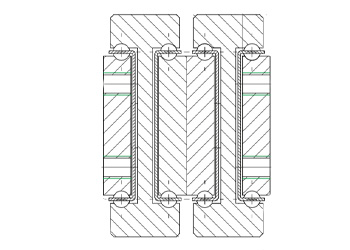

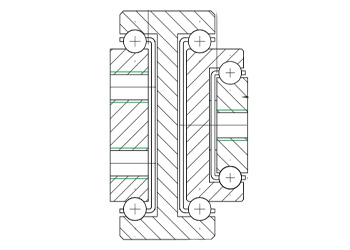

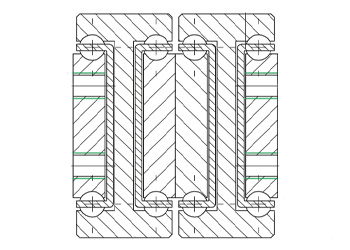

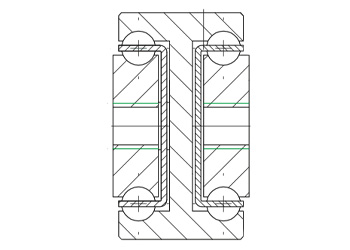

Telescopic slides full extensions 100%

Steel (C45E+C) galvanized, milled and hardened raceways, extendable on one or both sides.

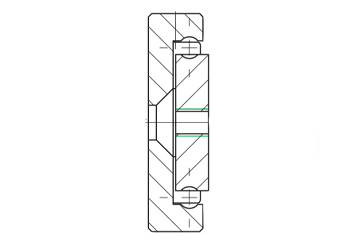

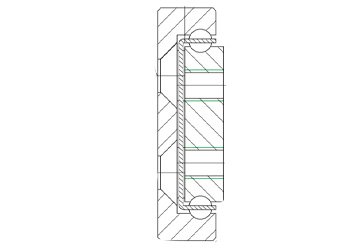

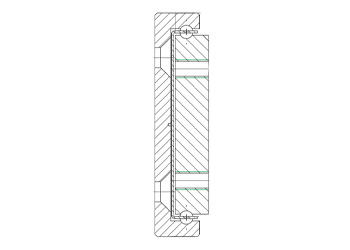

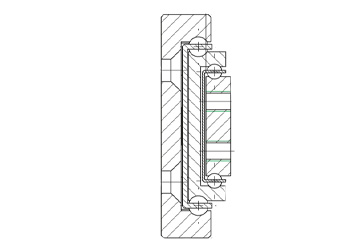

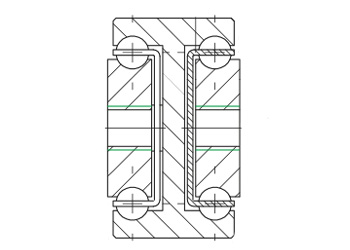

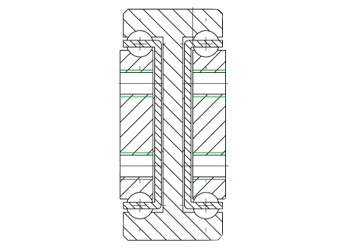

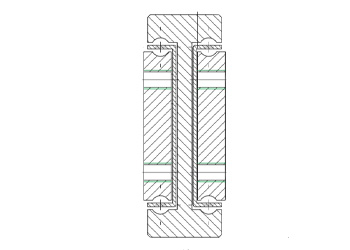

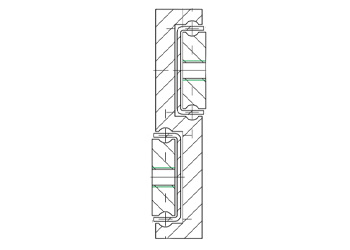

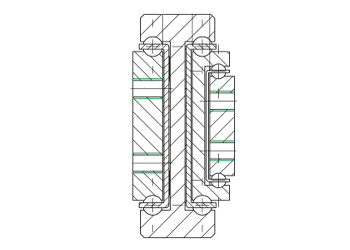

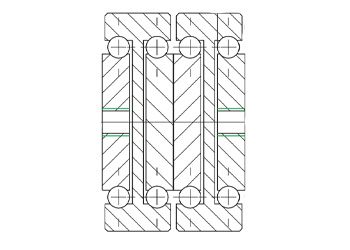

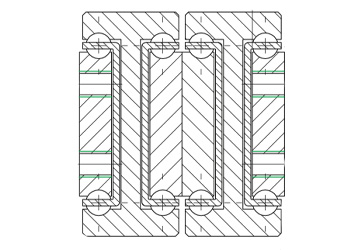

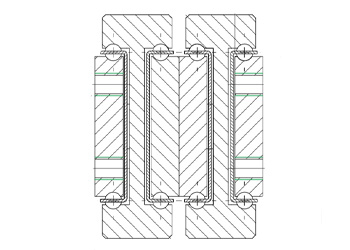

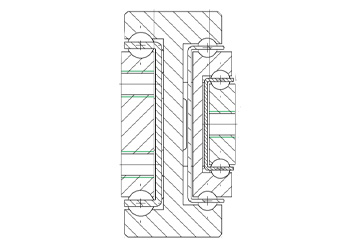

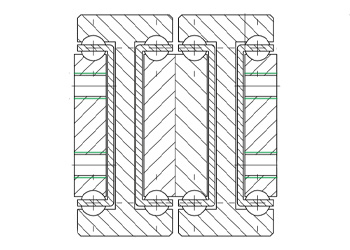

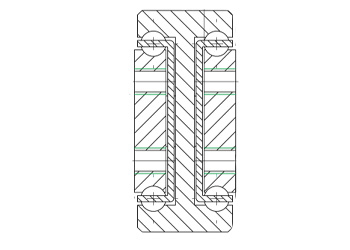

Telescopic slides over extensions 150%

Steel (C45E+C) galvanized, milled and hardened raceways, extendable on one or both sides.

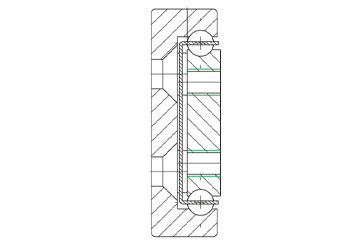

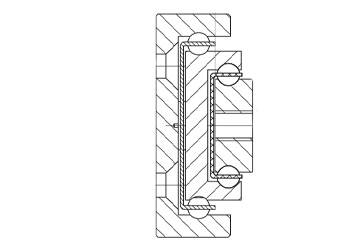

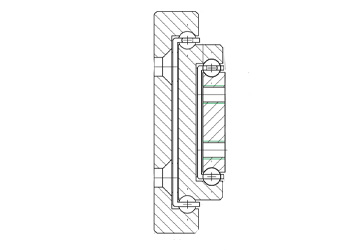

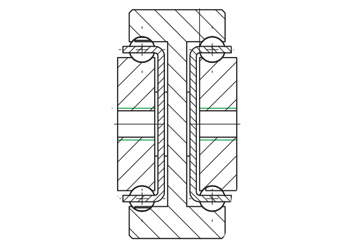

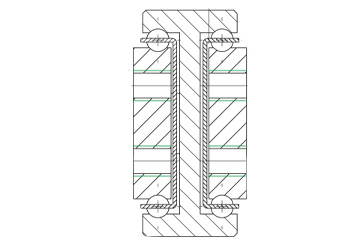

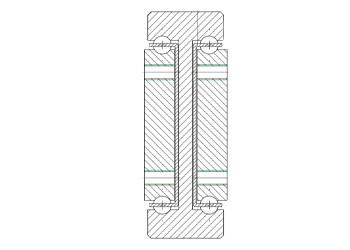

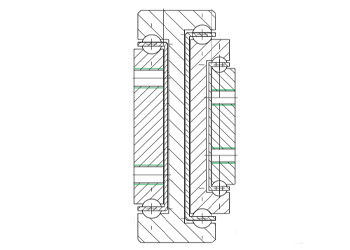

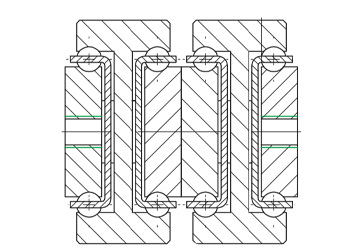

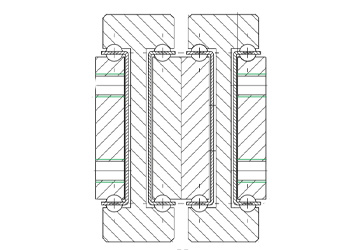

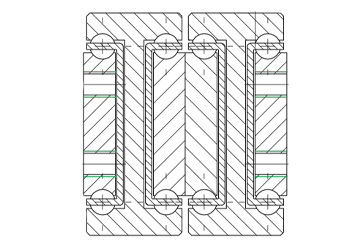

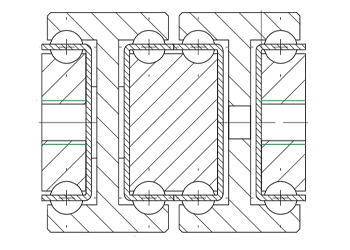

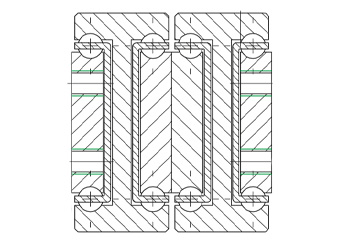

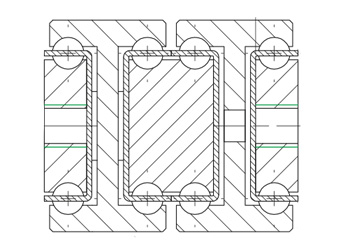

Telescopic slides super-over extensions 200%

Steel (C45E+C) galvanized, milled and hardened raceways, extendable on one or both sides.

Telescopic slides in stainless steel

Stainless steel V4A (1.4404, 316L), milled and hardened raceways, extendable on one or both sides.

Telescopic slides in aluminum

Aluminum (EN-AW 6082 T6), milled and hardened raceways, extendable on one or both sides.

Technical specifications (summary):

- Load capacity: up to 2,500 kg per pair of slides

- Length: up to 3,000 mm

- Deflection: minimal, thus very high bending stiffness

- Application area: Heavy-duty sectors, e.g., industrial plants, machine tools, heavy-duty drawers, special vehicle construction and wind turbines, and more.

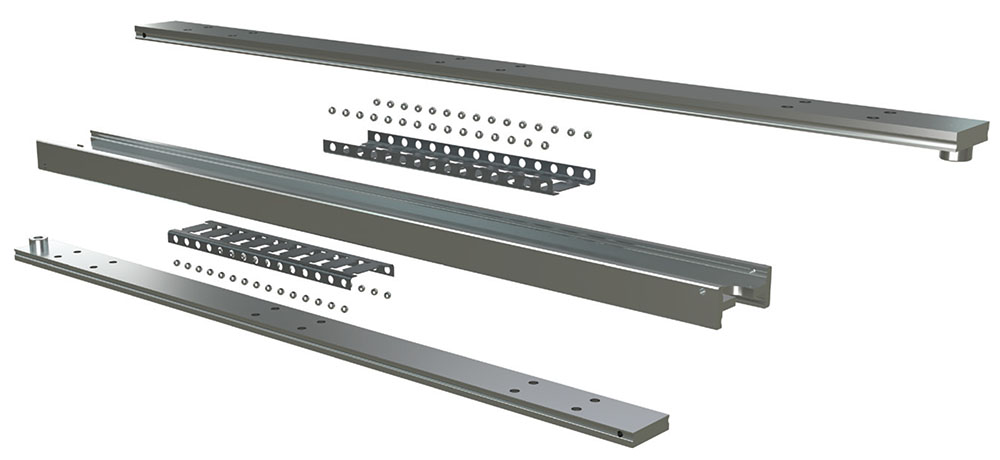

Telescopic slides from solid material – Robust, Precise, Customized

Our high-quality solid material telescopic slides offer maximum stability and durability – perfect for demanding applications in industrial and commercial sectors. You'll find the right extension variant with us:

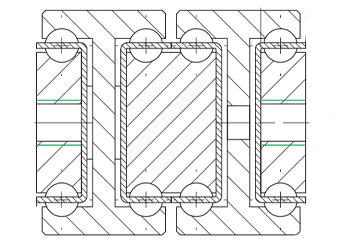

Partial extension (50% extension length)

Consisting of 2 profiles – ideal for applications with limited installation space.

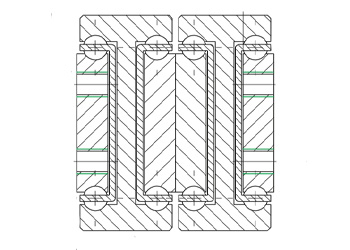

Full extension (100% extension length)

With 3 profiles – allows full access to the drawer.

Over-extension (up to 200% extension length)

3 to 5 profiles – maximum mobility for special requirements. Available as super over-extension with double extension length.

The telescopic slides are available in three material variants:

1. Galvanized carbon steel:

These slides are made from high-quality carbon steel and then galvanized to ensure improved corrosion resistance. They are suitable for a variety of industrial applications with medium corrosion protection requirements.

2. Stainless steel V4A (1.4404):

This variant offers maximum corrosion resistance and is often used in particularly demanding environments – such as inland and deep-sea shipping or wherever moisture and aggressive media are present.

3. Aluminum (EN-AW 6082 T6):

Aluminum telescopic rails are used wherever weight reduction is a priority – e.g., in aerospace, caravanning, or transport. They combine low weight with high stability and good corrosion resistance.

Delivery Times:

As these telescopic slides are specially manufactured for you after receiving your order, they have a delivery time of 15 to 20 working days.

Custom-made:

Do you have special requirements? No problem – we also realize customized solutions according to your wishes.