- Home

- /

- Technical details

Connecting Technology.

SCHOCK® Telescopic slides in detail.

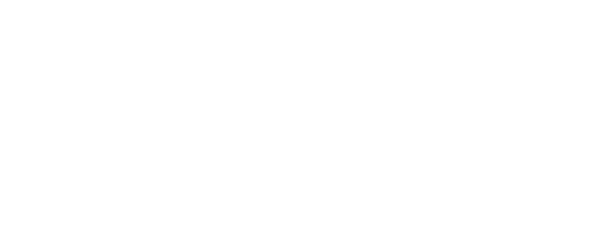

Structure of a roll-rormed telescopic slides with full or over-extension

- Outer rail

For mounting on the body or housing - Middle rail

Used for extending the extension to achieve full or over-extension - Inner rail

Attached to the pull-out element (e.g., drawer) - Ball cage

Secures the ball bearings for smooth, stable operation - Ball-Mix

With AIR MOTION technology – for exceptionally smooth and quiet operation - Function

Depending on the design, e.g., with soft-clos or disconnect

Operating temperatures of our standard telescopic slides

The operating temperatures of our standard telescopic slides are -20°C to +70°C.

When using a damped self-retraction, the operating temperatures are +10°C to +40°C. (Low-temperature applications are realized with specially developed dampers. Please contact our customer advisors for more information.)

For our milled super heavy-duty telescopic slides, the operating temperatures are -40°C to +200°C.

Extension options

SCHOCK® Telescopic slides

Partial extension (up to 75% extension length)

Consisting of 2 profiles – compact solution for limited installation space.

Partial extension extendable on both sides (up to 75% extension length)

Consisting of 2 profiles – compact solution for limited installation space.

The telescopic slides extend on both sides.

Full extension (100% extension length)

With 3 profiles – allows full access to the drawer.

Over-extension (up to 100% + extension length)

With 3 profiles – extension travel longer than the installed length.

Super over-extension (up to 200% extension length)

3 to 5 profiles – double installed length for maximum mobility to meet special requirements.

Robust, durable, and ready for peak performance: Materials of SCHOCK® telescopic slides.

Zinc-magnesium (ZM100 or Zinc+) Coated Sheet Steel

Technical description:

- Coating: Zinc-magnesium (e.g., 96% Zn, 3.5% Mg, 0.5% Al)

- Coating thickness: approx. 7–8 µm per side (equivalent to 50 g/m²)

- Standard: According to DIN EN 10346

- Corrosion protection class: Significantly better than conventional galvanized steel (e.g., GI Z100)

Properties:

- Excellent corrosion protection: Especially for edges and cut surfaces, thanks to passivating oxide layer

- Reduced material usage possible: Due to better protective effect, a thinner coating can be used

- High durability: Even in aggressive environmental conditions (e.g., rural, industrial or maritime atmosphere)

- Good formability and weldability

- More environmentally friendly: Lower zinc consumption, recyclable

Stainless Steel Sheet in 1.4301

Material 1.4301 is a stainless austenitic steel and belongs to the group of chromium-nickel steels. It is one of the most frequently used stainless steels in industrial and private sectors.

Properties:

- Corrosion resistance: Very good against water, humidity, diluted acids and many household chemicals – however, not seawater resistant.

- Weldability: Excellent – weldable without pre- or post-treatment.

- Polishability: Very good – suitable for decorative applications.

- Magnetizability: Not or only weakly magnetizable (in annealed condition).

- Formability: Very good cold formability.

Stainless Steel Sheet in 316l / 1.4404

Stainless steel 316L (material number 1.4404) is an austenitic chromium-nickel-molybdenum steel with particularly high corrosion resistance. The addition of molybdenum improves resistance to chlorides, acids and saline environments.

Properties:

- Excellent corrosion resistance, even in maritime and chemical environments

- Weldable and easily formable

- Resistant to many aggressive media (acids, alkalis, chlorides)

- Non-magnetic in annealed condition

Aluminum Sheet AlMg4.5Mn (EN AW-5083)

The aluminum sheet made of AlMg4.5Mn alloy belongs to the 5000 series (aluminum-magnesium alloys) and is characterized by very good corrosion resistance, high strength and good weldability. The addition of magnesium (approx. 4.5%) and manganese (Mn) gives the alloy excellent mechanical properties, even in welded condition.

Typical properties:

- Density: approx. 2.66 g/cm³

- Corrosion resistance: Very good – especially against seawater

- Strength: High, even after welding (higher than many other Al alloys)

- Weldability: Very good (MIG, TIG)

- Machinability: Medium – harder to machine due to its strength

- Not heat-treatable: Strength cannot be increased by heat treatment (only work-hardened)

Powder-coated telescopic slides, technology that's worth seeing.

SCHOCK® telescopic slides are not only functional and reliable, but also make a visual statement. This makes us the perfect choice for anyone who values an appealing appearance.

Starting from 250 pieces, you can get our rails in 9 standard RAL colors.

From 1,000 pieces, all RAL color shades are possible – individually adapted to your corporate identity or design requirements.

Your benefits at a glance:

- Extremely durable: The robust powder coating reliably protects against scratches, abrasion, and corrosion, making it ideal for heavily used applications.

- Our coating is durable and offers high color quality. It is UV-resistant and retains its color intensity even after years.

- Our surface is perfect. The paint application is always even, without runs, bubbles, or irregularities. The result is a professional, high-quality appearance.

- Our powder coating is solvent-free and thus environmentally friendly.

- Individual & flexible: The variety of colors allows our telescopic rails to be adapted to your product design.

With our powder-coated telescopic slides, you secure tested quality and design freedom in mechanical engineering, the furniture industry, medical technology, or for special applications.

Discover color variety now and design individuality as desired.

The SCHOCK standard RAL colors from 250 pieces:

- RAL 9003 Signal White

- RAL 9010 Pure White

- RAL 9011 Graphite Black

- RAL 7043 Traffic Grey

- RAL 7016 Anthracite Grey

- RAL 9006 White Aluminum

- RAL 7037 Dusty Grey

- RAL 8014 Sepia Brown

- RAL 5017 Traffic Blue