- Home

- /

- About Us

SCHOCK® GROUP, your strong partner.

Independent. Personal. Solution-oriented.

A strong network for end-to-end solutions

The SCHOCK® Group is a fully integrated corporate group. It encompasses individual ball guides, telescopic slides, special profiles, and the manufacturing of complex assemblies. SCHOCK® is known as an industry leader and offers a wide range of products and services used in various customer solutions.

Six locations in four countries form a seamless value chain:

From development to worldwide delivery, our customers receive everything from a single source – fast, reliable, on-time, and in the desired quality.

Our Competence Centers at a Glance | Locations

SCHOCK®

Urbach, Germany

At our company headquarters, founded in Urbach in 1971, 100% of our telescopic slides profiles are produced. Our in-house developed roll forming machines efficiently produce profiles with high precision. This manufacturing step forms the basis for our telescopic rails. Subsequently, the profile parts are sent to Liepaja in Latvia, where they are assembled, finished, and prepared for shipment to our logistics center at our plant.

SCHOCK®

Schopfloch, Germany

With an impressive storage and logistics area of over 10,000 m², Schopfloch is the central hub of the SCHOCK® GROUP. From here, we manage not only the worldwide distribution of our products but also sales and marketing for the entire corporate group. Short distances, efficient processes, and a strong team make this location the logistical control center of our international success story.

SCHOCK®

Hatzfeld-Reddighausen, Germany

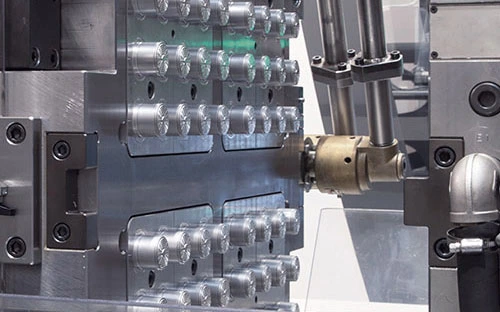

In Hatzfeld-Reddighausen, the SCHOCK® GROUP combines expertise, precision, and innovative strength. Both standardized and customer-specific telescopic rails are developed here. Thanks to in-house production of tools and operating equipment, SCHOCK® remains flexible and independent in implementing individual customer solutions. The range of services is complemented by state-of-the-art injection molding machines, on which technically sophisticated plastic parts are manufactured directly on site.

SCHOCK®

Liepaja, Latvia

Our plant in Liepaja, Latvia, is the competence center for the assembly and powder coating of our self-manufactured telescopic slides and assemblies. As a full-service provider, SCHOCK® Metal Latvia handles complete product manufacturing – efficiently, precisely, and across industries. Customers from industrial, furniture, and special solutions sectors benefit from well-thought-out processes, high vertical integration, and uncompromising quality “Made by SCHOCK®”.

SCHOCK®

Chesapeake, Virginia, USA

The central sales office of the SCHOCK® Group for the North American and Canadian markets is located in Chesapeake, Virginia. The company stands for customer-oriented service, technical expertise, and fast response times with its own warehousing. Thanks to its direct local presence, our customers benefit from short delivery routes, individual consulting, and customized solutions for ball-bearing telescopic slides.

SCHOCK®

Kemalpaşa, Turkey

Based in the industrial center of Kemalpaşa, SCHOCK® Metal Türkiye stands for technical competence, reliability, and customer proximity. As part of the globally successful SCHOCK® GROUP, we develop and distribute high-quality telescopic slide solutions for various applications in home appliances and automotive.

Whether customized special solutions or proven standards: SCHOCK® Metal Türkiye delivers technology that moves – for Turkey, the Middle East, and beyond.

SCHOCK Metallwerk: Moving since 1971

1971 – On October 1, 1971, the new metal plant in Urbach was opened – at that time still part of the Schorndorf company – and specialized in ball-bearing telescopic slides, decorative metals, and drawer runners for the furniture industry. Even then, the company employed over 1,200 people across several locations.

1978 – On July 1, 1978, the Urbach plant became legally independent and operated as Schock Metallwerk GmbH, under the leadership of Hermann and Richard Schock. This laid the foundation for the company's development as an independent player in the metal processing industry. In the following years, Schock established itself as a trustworthy partner in industry and trade.

2002 – Schock Metallwerk GmbH expands globally and structures the company into five strategic business units: Home Appliances, Automotive, Living/Storage, Industry and Trade. This diversification opens new markets and strengthens the company's international competitiveness.

2019 – In Liepaja, Latvia, a state-of-the-art assembly plant is opened. All SCHOCK® telescopic slides are completed at this plant. The highest quality standards are maintained here, and a final quality control is performed. This is how we guarantee the highest product quality.

2021 – The establishment of a logistics center in Schopfloch, Germany, optimizes worldwide shipping coordination and ensures efficient, on-time delivery to customers on all continents. This center is an important building block for the company's global logistics strategy.

2023 – Expansion of the logistics center in Schopfloch: A state-of-the-art powder coating plant is put into operation. Additionally, another warehouse with photovoltaics and 380 kW of power is built. These measures are key to greater sustainability and growth. Thanks to our photovoltaics, CO2 emissions could be significantly reduced and our operating costs lowered.

Quality

Schock Metallwerk GmbH is ISO 9001 certified and consistently implements the concept of Total Quality Management (TQM) across all company divisions. This comprehensive quality approach ensures that all company processes are carefully planned, controlled, and continuously optimized to achieve maximum efficiency and consistently high product quality.

By introducing and integrating advanced control systems into all production and work processes, it is ensured that every product meets the high requirements. The focus is on proactive error prevention to enable virtually flawless production. Zero-defect production is not just a goal, but an integral part of daily work within the SCHOCK® Group.

Regular customer audits provide another important building block of quality management. These audits create transparent communication and ensure that customer requirements are always met. Furthermore, preventive quality assurance measures are taken in the early phase of production to identify and eliminate potential sources of error before they affect the final product.

Through this systematic approach, SCHOCK® has created a solid foundation for delivering innovative and high-quality products.

Sustainability

SCHOCK® takes its responsibility towards the environment with the highest priority and commitment. The company consistently pursues sustainable production and continuously works to minimize environmental impact.

Our products are characterized by their durability and maintenance-free nature – qualities that not only extend the lifespan of the products but also reduce their ecological footprint. By selecting environmentally friendly materials and developing long-lasting solutions, we actively contribute to conserving resources and protecting the environment.

The SCHOCK® GROUP is committed to driving sustainable innovations and acting responsibly in the future, thereby further reducing our ecological footprint and contributing to environmental preservation.

By completing the EcoVadis questionnaire, we have taken an important step to have our sustainability performance evaluated – with the goal of transparently presenting our environmental and social responsibility to our customers.

One Corporate Group. One Promise.

We rely on in-house production and a seamless supply chain.

Quality you can rely on.

The manufacturing process starts with the production of our tools in our own toolmaking department. The production of our telescopic guides is carried out entirely in-house. This allows us maximum flexibility and cost control, and thus absolute control over all details.

Every manufacturing step is subject to strict testing processes. This ensures that every product meets our customers' high demands for dimensional accuracy, load capacity, and functionality.

Construction and development

- Co-engineering

- Product design

- Prototype construction

- 3-D simulation

- Testing and test laboratory

Roll forming technology

- Individual profile shapes

- High material utilization

- Energy-efficient manufacturing process

- Highest precision

Metal Processing

- Punching

- Bending

- Embossing

- Welding

- 3-D laser technology

Surface finishing

- Powder Coating

- Galvanization

- Cathodic dip coating (CDC)

Injection Molding

- Injection molding production

- 1 and 2 component plastic parts

- Small and large series

Mold and tool making

- Construction

- Production

- Tool management

Assembly Production

- Assembly and packaging

- Manufacturing of complex assemblies

- Packaging

Logistics HUB / Online retail

- European logistics center

- Order picking and packaging

- Worldwide transport and logistics service